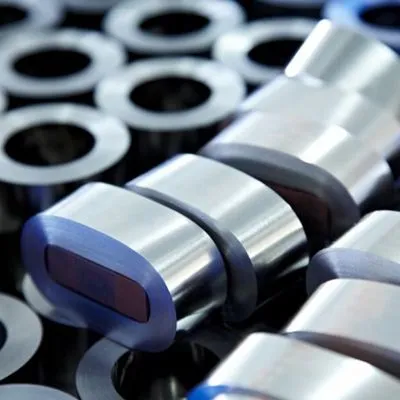

Amorphous ribbon is a type of soft magnetic materials that have gained popularity internationally over the past two decades as novel materials for laminated cores in place of traditional silicon cores. In comparison to traditional silicon steel sheets used for transformer manufacturing, amorphous ribbon cores offer several advantages, including higher magnetic induction strength, lower eddy current losses, and hysteresis losses. Currently, the cores made by amorphous ribbons are widely employed in the production of transformers, inductors, motors, reactors, and other related products.

We are a manufacturer specializing in the manufacture and supply of amorphous ribbon core cutting machines. Moreover, we are also a reliable partner for transformer manufacturers, manufacturing companies of transformer cores and core laminations to develop transformer core production solutions that are comprehensive to satisfy the requirements of specifications and demands.

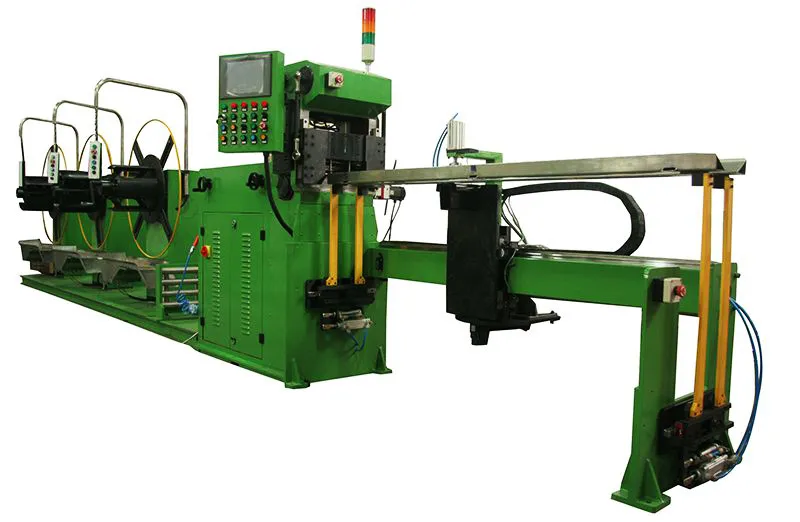

We offer complete amorphous core cutting machine solutions that are tailored to the application scope and customer requirements for cores. They mainly consist of transformer core cutting machine mated with a range of auxiliary equipment including annealing furnace, drying tunnel oven, 90-degree tilt table and core stacking table. Our transformer core cutting machine is suitable for cutting amorphous ribbons ranging from 140 to 213mm in width, which are used in the production of both amorphous C cores and toroidal cores.

Whether you are a transformer manufacturer looking for transformer core cutting machine or an amorphous ribbon supplier in need of equipment for amorphous laminations, we have customization service to meet your individual requirements.

Amorphous ribbon core cutting machine is a system designed for the production of amorphous cores. The primary processes involved in this transformer core cutting machine include cutting, annealing, drying, tilting (overturning), testing, and more. These processes are executed with high efficiency and precision to manufacture amorphous cores.

Amorphous Core Cutting Machine

Cut to length line for cutting and stacking of amorphous cores

Amorphous Core Cutting Machine

Cut to length line for cutting and stacking of amorphous cores

Amorphous cores are becoming a popular choice by transformer manufacturers because that using the amorphous metal core allows to build smaller transformers and generate lower noise when compared to silicon steel core transformer. Furthermore, amorphous core transformers have been found to be more energy efficient than silicon steel core transformer, primarily due to its better core loss reduction.

DetailsIn addition to providing complete transformer core production system that conducts tilting, cutting, core forming, annealing, coating and testing for making amorphous cores used in transformers, inductors, motors and reactors, we also assist customers in designing, manufacturing and training to meet their specific needs.

We specialize in providing transformer core cutting machines and associated equipment, such as annealing furnaces, drying tunnel ovens, core stacking tables, and more. Please contact us for more information.

Amorphous cores produced by our amorphous ribbon core production line have several advantages: